Technologies

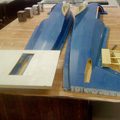

Manual lamination - applying gelcoat to the mould and gradual saturation of fibreglass by epoxy resin. The product is then hardened either freely or by using heat through vacuum technology.

RTM technology (injection moulding) - convenient for larger batches, made in closed moulds, the advantage of this method is that both surfaces of the product are absolutely smooth after hardening.

Production of 3D models, their surface finishing and complete design before making the final mould.

We will gladly discuss with you the design and the options concerning the technology of the production. We guarantee close cooperation during the whole process – from making a 3D model based on the technical documentation to the final product.

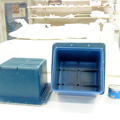

Production of laminate moulds characterized by remarkable durability and high temperature resistance.

At your request, we can make a mould of any shape and surface that is to be transferred on the product.

Manufacturing of laminate of any colour or metallic paint of a high gloss. Another option is only a fundamental form in order to enable an additional modification. Production of strong industry materials, aircraft laminates for ultralight airplanes or laminate for airplane models.